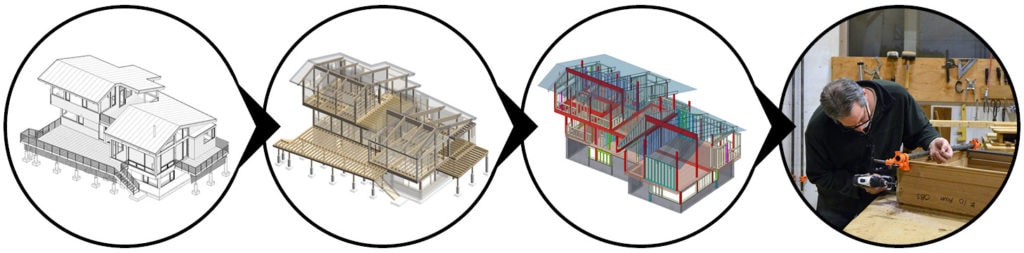

Panelization & Fabrication

Panelization is the process in which construction drawings are digitally broken down and labeled into individual components. Fabrication is the manufacturing process of these components in the optimal conditions of our climate-controlled indoor environment, which eliminates site-built uncertainties (i.e. weather).

Panelization & Fabrication Benefits

- Factory-built components fabricated under optimum conditions

- Fast, efficient construction of a weather tight shell on site

- Precision joinery that enhances fit and increases energy efficiency

- Pre-cut and pre-assembled components that minimize resource waste and disposal costs on site

- Unique floor systems that facilitate installation of mechanicals

- Materials delivered to coordinate with your builder’s schedule

What We Do

Acorn Deck House Company Component Packages include all of the materials required to create a weathertight shell along with the specialty millwork used in the interior. Major components are meticulously precut and detailed for tight tolerances and an accurate fit. Our proprietary millwork – including mahogany entry doors, mahogany windows and sliding glass doors, magnificent stair and rail systems and trim styles – is hand crafted and designed for modern lifestyles.

- Window sizes and shapes are manufactured to meet your desire for uninterrupted walls of glass as well as your need for privacy in certain areas

- Specialty engineered floor systems offer superior strength and allow for installation of plumbing, heating and wiring with minimum on site cutting

- Beams and other structural members are pre-cut and pre-drilled to conceal connecting hardware

- Wall panels have tight tolerances and high structural integrity

- Pre-engineering reduces framing time and dramatically reduces waste

- Specialty millwork products complement the overall design